Accelerated Stress Testing forces product failures faster than conventional testing methods. HALT Testing gives an accelerated view of how your product will react in different environments and how long it can handle it before it fails.

Thermotron’s Accelerated Stress Testing climatic chambers are equipped with innovative, state-of-the-art features for effective HALT (Highly Accelerated Life Testing) and HASS (Highly Accelerated Stress Screening) including: change rates up to 70°C/minute, adjustable air distribution, multi-functional controller, ergonomic workstation, and multiple safety features.

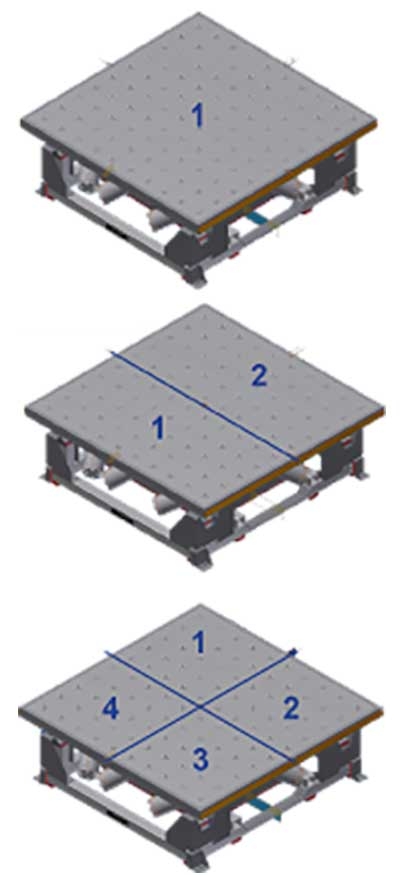

Combining extreme temperature change rates with repetitive shock vibration testing provides a unique and forceful testing experience to determine the product’s operating and destruct limits. The vibration testing used for HALT/HASS is conducted with Thermotron’s patented multi-axis repetitive shock vibration table, which can be configured to provide superior uniformity across the entire table with the exclusive, patented Multi-Zone Control.

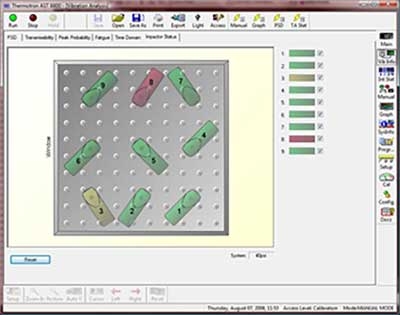

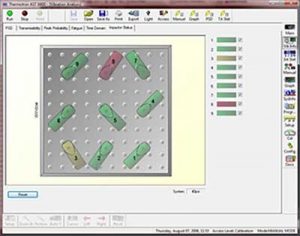

The impactor monitor system visually illustrates the impactor’s status on the screen. A red impactor indicates the system cannot compensate enough air pressure and needs to be replaced. The AST-8800 monitors the air pressure to each impactor anytime the system is running. The benefit of adjusting air pressure is that test results are more consistent and accurate.

The impactor monitor system visually illustrates the impactor’s status on the screen. A red impactor indicates the system cannot compensate enough air pressure and needs to be replaced. The AST-8800 monitors the air pressure to each impactor anytime the system is running. The benefit of adjusting air pressure is that test results are more consistent and accurate.