Versatile. Flexible. Powerful.

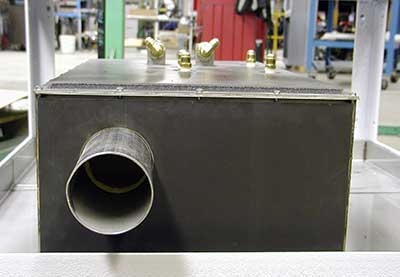

Thermotron AGREE Test Chambers provide the flexibility to adapt to your ever-changing environmental testing requirements. The chambers are available in temperature-only or temperature and humidity configurations. Rapid thermal change rates of 5°C up to 30°C are available. These environmental chambers can become vibration chambers when seamlessly integrated with a Thermotron electrodynamic shaker or repetitive shock vibration table.

This diversifies the chamber’s utility because it can be used as a standalone temperature environmental chamber or for combined environmental testing. Thermotron AGREE Chambers were originally designed for the defense and aerospace industry to perform temperature, humidity, and vibration tests conforming to MIL-STD 781 and 883. Since then, AGREE Vibration Chambers have been adapted to perform reliability, qualification, and Environmental Stress Screening (ESS) for a wide range of industries including electronics, aerospace, automotive, and telecommunications industries.