Do you have something small you need to test?

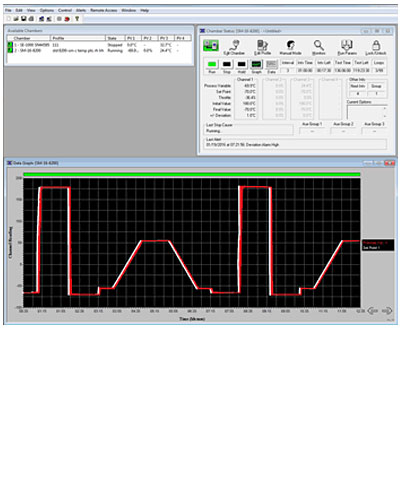

A Benchtop Environmental Chamber offers flexibility, uniformity, and control accuracy required for cost-effective environmental testing. Ideal for testing smaller products such as computer components, automobile sensors, or cell phones, a Thermotron Benchtop Environmental Chamber combines superior performance in a small, compact design well suited for research and development or personal point-of-use testing. With a wide breadth of configurations including various options for temperature testing or temperature and humidity testing, this small environmental chamber is Ethernet enabled, easy to install, and ready to work.