Altitude Test Chambers combine temperature and altitude environments with optional humidity for simultaneous environmental testing. An Altitude Chamber allows users to control the test chamber temperature while subjecting the product under test to various levels of altitude up to 100,000 feet, with optional extended altitude range to 150,000 feet. This combination of elements allows precise simulation of real-life conditions a product might encounter at various altitude levels.

Altitude Chamber

| Model Number | Workspace Dimensions | Cooling Performance | |

|---|---|---|---|

| FA-4-CH-1-1 Altitude Chamber | 4 ft³ 113 L |

-73°C to 177°C (-100°F to 350°F) |

|

| FA-10-CH-3-3 Altitude Chamber | 10 ft³ 283 L |

-73°C to 177°C (-100°F to 350°F) |

|

| FA-10-CH-5-5 Altitude Chamber | 10 ft³ 283 L |

-73°C to 177°C (-100°F to 350°F) |

|

| FA-16-CH-3-3 Altitude Chamber | 16 ft³ 453 L |

-73°C to 177°C (-100°F to 350°F) |

|

| FA-16-CH-5-5 Altitude Chamber | 16 ft³ 453 L |

-73°C to 177°C (-100°F to 350°F) |

|

| FA-35-CH-5-5 Altitude Chamber | 35 ft³ 991 L |

-73°C to 177°C (-100°F to 350°F) |

|

| FA-35-CH-7.5-7.5 Altitude Chamber | 35 ft³ 991 L |

-73°C to 177°C (-100°F to 350°F) |

|

| FA-46-CH-7.5-7.5 Altitude Chamber | 46 ft³ 1,302 L |

-73°C to 177°C (-100°F to 350°F) |

|

| FA-64-CH-7.5-7.5 Altitude Chamber | 64 ft³ 1,812 L |

-73°C to 177°C (-100°F to 350°F) |

|

| FA-64-CH-15-15 Altitude Chamber | 64 ft³ 1,812 L |

-73°C to 177°C (-100°F to 350°F) |

|

| FA-96-CH-7.5-7.5 Altitude Chamber | 96 ft³ 2,718 L |

-73°C to 177°C (-100°F to 350°F) |

|

| FA-96-CH-15-15 Altitude Chamber | 96 ft³ 2,718 L |

-73°C to 177°C (-100°F to 350°F) |

|

| FA-10-CHM-3-3 Humidity Altitude Chamber | 10 ft³ 283 L |

-73°C to 177°C (-100°F to 350°F) |

|

| FA-10-CHM-5-5 Humidity Altitude Chamber | 10 ft³ 283 L |

-73°C to 177°C (-100°F to 350°F) |

|

| FA-16-CHM-3-3 Humidity Altitude Chamber | 16 ft³ 453 L |

-73°C to 177°C (-100°F to 350°F) |

|

| FA-16-CHM-5-5 Humidity Altitude Chamber | 16 ft³ 453 L |

-73°C to 177°C (-100°F to 350°F) |

|

| FA-35-CHM-5-5 Humidity Altitude Chamber | 35 ft³ 991 L |

-73°C to 177°C (-100°F to 350°F) |

|

| FA-35-CHM-7.5-7.5 Humidity Altitude Chamber | 35 ft3 991 L |

-73°C to 177°C (-100°F to 350°F) |

|

| FA-46-CHM-7.5-7.5 Humidity Altitude Chamber | 46 ft³ 1,302 L |

-73°C to 177°C (-100°F to 350°F) |

|

| FA-64-CHM-7.5-7.5 Humidity Altitude Chamber | 64 ft³ 1,812 L |

-73°C to 177°C (-100°F to 350°F) |

|

| FA-64-CHM-15-15 Humidity Altitude Chamber | 64 ft³ 1,812 L |

-73°C to 177°C (-100°F to 350°F) |

|

| FA-96-CHM-7.5-7.5 Humidity Altitude Chamber | 96 ft³ 2,718 L |

-73°C to 177°C (-100°F to 350°F) |

|

| FA-96-CHM-15-15 Humidity Altitude Chamber | 96 ft³ 2,718 L |

-73°C to 177°C (-100°F to 350°F) |

Standard

- 3" (7.5 cm)

- 4" (10 cm)

- 5" (12.5 cm)

- 6" (15 cm)

- 8" (20 cm)- HALT Chamber Only

Access Port

The following are the most standard sizes:

Shelves

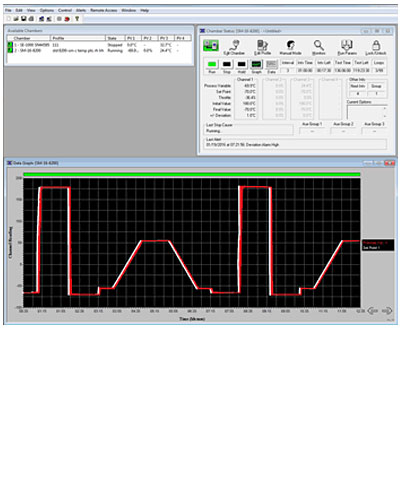

ThermoTrak II

| ThermoTrak II Software Specifications | |

|---|---|

| Thermotron Controllers Supported | 2800, 3200, 3800, 4800, 6850, 7800, 7825, 8200, 8800, 8825, Oven |

| Interface Capabilities | RS232, RS485, GPIB (IEEE-488), Ethernet (TCP/IP) |

| Maximum Number of Controllers | Up to 32 |

| Maximum Control Channels | 4 (controller dependent) |

| Data Log/Graph Resolutions | Adjustable per controller; 2-3,600 second increments |

| Maximum Graph/Data Log Display Readings | 32,000 per logged item |

| Maximum Data Log File | Limited only by hard drive space |

| Operating System Required | Microsoft Windows® 95, 98, 2000, NT, XP, Vista, 7, or 10 |

Interior Light

Therm-Alarm

Optional

-

Air Cooled Condenser

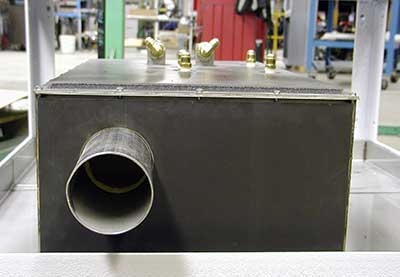

Air Cooled Condensers for environmental chambers take the heat of out the equipment's refrigeration system. On smaller and standard Thermotron environmental equipment, the air-cooled condenser is located inside the environmental chamber. A remote air-cooled condenser is available for equipment with higher performance requirements or larger compressors. Water-cooled condensers may also be available, depending on environmental chamber model. Contact your local sales representative for more information.

Air Cooled Condensers for environmental chambers take the heat of out the equipment's refrigeration system. On smaller and standard Thermotron environmental equipment, the air-cooled condenser is located inside the environmental chamber. A remote air-cooled condenser is available for equipment with higher performance requirements or larger compressors. Water-cooled condensers may also be available, depending on environmental chamber model. Contact your local sales representative for more information. -

Custom Colors

You are probably used to only seeing a Thermotron environmental chamber or electrodynamic shaker in just one of two colors – blue and gray. But we can in fact paint your piece of test equipment any color you like, provided you let us know which one.

Custom paint color is an available optional feature for equipment purchased from Thermotron, and the process is quite simple. During the quote process, you work with our Sales and Application Engineers and simply notify them what color you want your test equipment to be painted. We primarily work with RAL and FED-STD-595C – Color Standards, but if you provide us with a color and the standard it comes from we will work with our paint supplier to ensure that your environmental chamber or electrodynamic shaker is painted your specified color.

So, why would you want to have your climate chamber painted a different color? There are many reasons here are a few of the most common:

- Branding – customers want to have their equipment painted to promote their brand, and incorporate their branding colors into items their staff and customers see every day.

- Grouping – Some customers with many Thermotron chambers in their lab need them to be color coordinated by function, ability, or size.

- Safety – We have also had customers request that only certain parts of the environmental chamber or electrodynamic shaker are painted. For example we had a customer paint all electrical panels bright orange to highlight potential safety hazards.

-

Quiet Package

A quiet package is an optional feature that minimizes the noise levels coming from environmental test equipment. Depending on the equipment (electrodynamic shaker or climate chamber) and the size of the environmental test equipment, the quiet package will look and vary in functionality. For more information contact your local sales representative.

A quiet package is an optional feature that minimizes the noise levels coming from environmental test equipment. Depending on the equipment (electrodynamic shaker or climate chamber) and the size of the environmental test equipment, the quiet package will look and vary in functionality. For more information contact your local sales representative. -

Water Purification and Recirculation System

The Water Purification and Recirculation System is an optional feature on humidity systems for Thermotron equipment. This system purifies water to be within the recommended working limits of the chamber and the recirculation aspect takes water that has already be used in the humidity system and reuses it after it has been purified.

The Water Purification and Recirculation System is an optional feature on humidity systems for Thermotron equipment. This system purifies water to be within the recommended working limits of the chamber and the recirculation aspect takes water that has already be used in the humidity system and reuses it after it has been purified. -

CSA or CE Electrical Codes

For equipment going to Canada or the European Union, Thermotron can build the equipment to CSA or CE electrical codes to ensure the safety of equipment users and the facility.

For equipment going to Canada or the European Union, Thermotron can build the equipment to CSA or CE electrical codes to ensure the safety of equipment users and the facility. -

Humidity

Many Thermotron environmental chambers have the optional feature of humidity to diversify the utility of the climatic chamber. Precise uniformity and tight control characterize the high-performance specifications of the humidity system. Thermotron humidity systems can be configured for a direct-feed facility hook-up or using a water reservoir. The system’s steam generator achieves high volumes of moisture with consistent water vapor levels and more repeatable test result.

The SE-Series Temperature Humidity Chambers have a patented, modular, full-range humidity system. This allows a temperature chamber to be retrofitted and upgraded to a temperature humidity chamber.

Humidity tests can be monitored through the environmental chambers’ controllers.

-

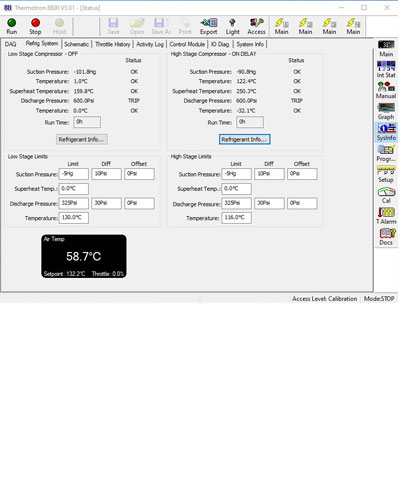

System Monitor

Thermotron's built-in System Monitor streamlines troubleshooting by providing continuous self-diagnostics on refrigeration suction/discharge pressures and temperatures. This reduces maintenance and troubleshooting time by indicating the system malfunction or trip. The feature also tracks running time to aid in preventive maintenance scheduling and restarts the chamber after nuisance trip or power loss (different restarts can be programmed as well).

Thermotron's built-in System Monitor streamlines troubleshooting by providing continuous self-diagnostics on refrigeration suction/discharge pressures and temperatures. This reduces maintenance and troubleshooting time by indicating the system malfunction or trip. The feature also tracks running time to aid in preventive maintenance scheduling and restarts the chamber after nuisance trip or power loss (different restarts can be programmed as well). -

Window

Almost all Thermotron chambers come with one standard window. Additional windows are available. Widows can also be custom sized and shaped to accommodate product viewing. Consult with your local sales representative for more information.

Almost all Thermotron chambers come with one standard window. Additional windows are available. Widows can also be custom sized and shaped to accommodate product viewing. Consult with your local sales representative for more information.

"*" indicates required fields