Let’s move some products

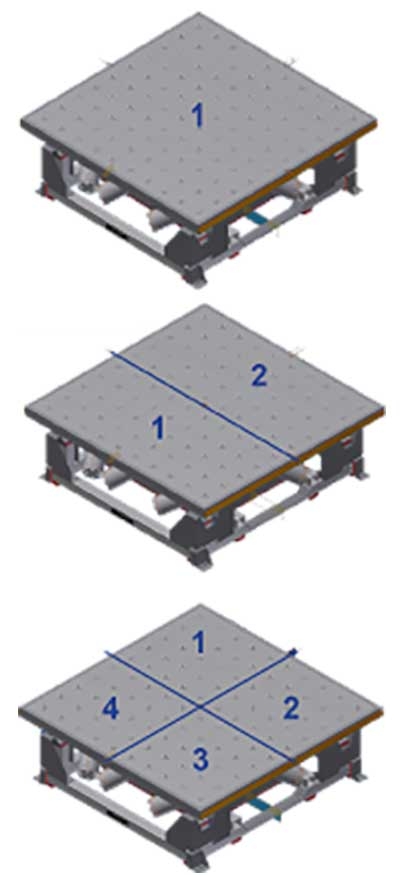

Repetitive Shock Vibration tables generate multi-axis vibration using one or more pneumatic impact hammer(s) (also known as impactors) that strike the bottom of the vibration table on which a product is attached. Thermotron’s repetitive shock vibration test systems are designed specifically for very aggressive temperature change rates and high levels of multi-axis repetitive shock vibration.

Repetitive shock shaker tables can be used as stand-alone units or combined with an AGREE or AST chamber for HALT/HASS testing. The repetitive shock vibration system incorporates many unique features designed to satisfy a wide range of vibration testing and screening applications for many industries.

The basic system utilizes Multi-Zone Control. This patented feature uniformly—and more effectively—tests products. As a result, you receive improved product reliability, reduced warranty and recall risks, as well as better-utilized company resources.

The air glide allows a vibration shaker to be effortlessly pulled and pushed from below an environmental chamber. A lever on the pull bar engages the air glide feature so the electrodynamic shaker or repetitive shock vibration table rides on a cushion of compressed air. This makes it convenient to pull the vibration shaker completely out of the environmental chamber and then walk all the way around to configure products mounted on the back of the vibration table.

The air glide allows a vibration shaker to be effortlessly pulled and pushed from below an environmental chamber. A lever on the pull bar engages the air glide feature so the electrodynamic shaker or repetitive shock vibration table rides on a cushion of compressed air. This makes it convenient to pull the vibration shaker completely out of the environmental chamber and then walk all the way around to configure products mounted on the back of the vibration table.

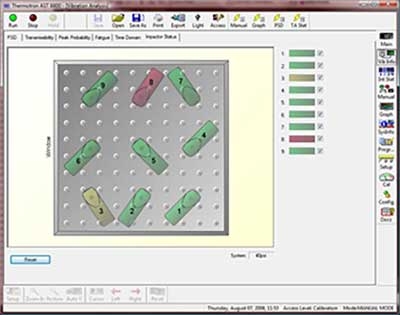

The impactor monitor system visually illustrates the impactor’s status on the screen. A red impactor indicates the system cannot compensate enough air pressure and needs to be replaced. The AST-8800 monitors the air pressure to each impactor anytime the system is running. The benefit of adjusting air pressure is that test results are more consistent and accurate.

The impactor monitor system visually illustrates the impactor’s status on the screen. A red impactor indicates the system cannot compensate enough air pressure and needs to be replaced. The AST-8800 monitors the air pressure to each impactor anytime the system is running. The benefit of adjusting air pressure is that test results are more consistent and accurate.