Utilizing the humidity feature of an environmental test chamber helps determine how a product performs in high humidity environments. Have you ever considered the water used in your humidity chamber? The quality of water used is the most overlooked component of a humidity system.

Utilizing the humidity feature of an environmental test chamber helps determine how a product performs in high humidity environments. Have you ever considered the water used in your humidity chamber? The quality of water used is the most overlooked component of a humidity system.

While it may not seem to matter what water is used in your test chamber, that is far from the truth. Tap water, for example, contains many impurities, such as calcium, magnesium, sodium, potassium, chloride, nitrates, iron, and copper, among others.

These impurities dissolve in water, but when they run through an environmental test chamber’s humidity system, there can be devastating effects:

- Heater failure

- Excess scale and mineral deposits in the vapor generator

- Poor humidity control or possible nuisance trips

Using water with the appropriate purity levels is quite important as it helps to reduce required maintenance and can avoid damaging the humidity chamber components or other equipment. Depending on the water piped into a facility, the following water purification options can be appropriate or even necessary: distillation, reverse osmosis, deionization, mechanical filtration, and UV sterilization.

If you plan on using any of these techniques to purify the water that feeds into the humidity chamber, it is recommended that the water follows Thermotron’s humidity water requirements:

Resistivity – Between .05MΩ-cm to 3MΩ-cm (SM chambers require .05MΩ-cm to 1MΩ-cm)

Turbidity – Less than 5 NTU

Chlorine free – Less than .2 parts per million

Color – Less than 5 TCU

Total iron & manganese – Less than .3 parts per million

Organics – Less than 1 part per million

Acidity – 6.8 to 7.2 pH

Caution must also be taken with purified water. Too pure of water can also have damaging effects on a chamber, ranging from mineral leaching of the chamber or product to corrosion of the humidity system.

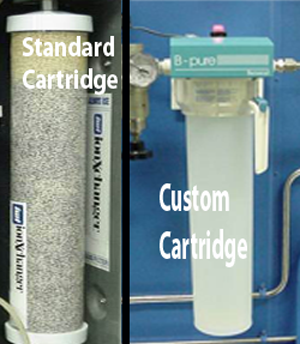

Many Thermotron humidity chambers come conveniently equipped with a water purification system, which takes standard tap water and processes it for safe use in the environmental test chamber. However, depending on incoming water quality, this water purification system may be inadequate and another filtration system may be necessary for incoming water.

Thermotron’s water purification system contains both a filter, which removes non-dissolved solids, and a deionizer, which chemically removes ions from the water. Dissolved ions replace hydrogen (H+) and hydroxyl (OH-) as contaminated water passes through the mixed bed of the deionizer. Then, the released hydrogen and hydroxyl combine to form water molecules. Each deionizer has a specific capacity for ions, and the useful life of the deionizer cartridge is subject to the quality of water used and the frequency of its use. Depending on the type of humidity chamber, the deionization cartridge will either change color or a red light will turn on to indicate the cartridge is spent, signaling when the cartridge needs to be replaced.

Water purity is an important aspect of using your environmental test chamber’s humidity system. Following Thermotron’s water purity requirements will increase the humidity system’s efficiency and decrease humidity-related service calls to your facility and test chamber, saving you time and money.