Creating and designing a product aren’t enough on their own. You need to ensure your product will function as it should after shipment and during routine use in the field. Even if the product in the continuously used in the same location, think of how much a normal use environment can change from season to season. As environmental stresses are applied, the physical and electrical characteristics of products can vary greatly.

Creating and designing a product aren’t enough on their own. You need to ensure your product will function as it should after shipment and during routine use in the field. Even if the product in the continuously used in the same location, think of how much a normal use environment can change from season to season. As environmental stresses are applied, the physical and electrical characteristics of products can vary greatly.

In environmental testing, temperature, humidity, and vibration are common environmental stresses applied to products. The environmental stresses appropriate for testing any specific product depend on the product’s design and components, and the end goal of the test.

Temperature, the most common environmental stress, affects products in a variety of ways. Changes in electrical constants due to temperature swings can cause unforeseen problems in the product’s function. Mechanical issues akin to expansion and contraction can become evident when the coefficient of thermal expansion does not match. Interactions of dissimilar materials, changes in flexibility, and PCB delamination can all occur when temperature stresses are used to uncover problems in the product’s design.

Humidity can cause physical changes, such as swelling and embrittlement for some materials, causing the product to malfunction or break. Oxidation (corrosion) and leakage paths between conductors are also exposed when extreme humidity conditions are present.

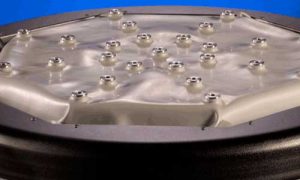

Vibration stresses can cause a loss of mechanical strength from fatigue, cracking, displacement, or the impairment of the product’s mechanical functions. This is true for both electrodynamic and repetitive shock vibration.

Altitude, corrosion, and sand and dust tests are other environments that can be used to stress products, though they are less common. Altitude testing is usually combined with temperature-humidity testing to simulate airplane components or test items that will ship via air or be used in high altitude climates. Corrosion tests are performed to determine a material’s sensitivity and reactions to salt water spray, for example. Sand and dust tests place a product in a workplace and send puffs of sand and dust into the air to settle on the product to see how it reacts over time.

By diversely and thoroughly stressing products, you can ensure your product will operate as intended in its normal use environment. Trying to replicate these stresses without the proper equipment can be a challenging undertaking with poor or disappointing results. Environmental test chambers and vibration shaker systems like the ones manufactured by Thermotron are essential to consistent and dependable results.